Oct 24,2023

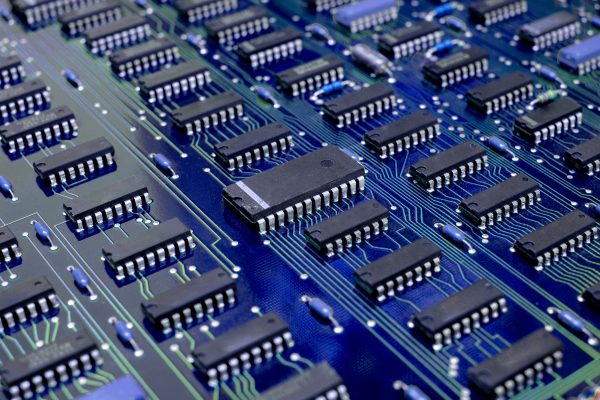

In electronics, each component's role ensures seamless functionality and intricacy. PCB connectors, often overlooked, enable signal and power flow in electronics. They are crucial components in electronic devices. The selection of the right PCB connector is paramount for the overall performance and reliability of the system. This guide will unravel the key considerations and steps to help you choose the perfect PCB connectors for your applications.

Understanding PCB connectors' significance precedes the selection process in electronics. These connectors play a crucial role in electronic circuitry. PCB connectors link circuit parts in Printed Circuit Board connections. They allow easy connection and disconnection of circuits. This permits simple maintenance and design flexibility. Various types of connectors are available: wire-to-board, board-to-board, and edge connectors. Each type is designed for specific applications.

The first step in choosing PCB connectors is identifying the application they will serve. Different applications have distinct requirements, which dictate the type of connector needed. Connectors for high-speed data differ from those in power distribution. Understanding these requirements is crucial for ensuring optimal performance and reliability.

Various PCB connectors are available, each designed to serve specific purposes. Pin headers, sockets, USB connectors, and RJ45 connectors are examples. Connectors vary in form: right-angle or surface mount for space considerations. Design preferences guide the choice of connector form in different applications. Understanding the specific needs of your application will guide you toward the right type and form factor of connector.

PCB connector's electrical specs are crucial for smooth signal transmission. They play a key role in ensuring signals pass without interference. Factors like voltage, current, signal integrity, and impedance matching are crucial in connector selection. Selecting connectors that can be crucial for both load handling and signal integrity. The connector's material is crucial for electrical performance. Additionally, it must be considered.

Durability matters greatly in choosing connectors. Mechanical robustness is equally important. This is especially true in harsh environmental conditions. Connectors need to withstand such conditions effectively. Think about insertion/extraction forces and mating cycles. Also, consider environmental sealing for connector durability. This ensures they can withstand the application's demands effectively.

Selecting connectors with correct specs ensures system durability and reliability.

Environmental conditions greatly affect PCB connector performance in electronic devices. Temperature variations, moisture, and exposure to chemicals are factors that must be taken into account. Choosing connectors with suitable IP ratings guarantees they endure specific environments.

Ensuring compatibility with other components in the system is crucial for seamless operation. Consider industry standards such as USB, HDMI, and others relevant to your application. Additionally, verify that connectors from different manufacturers can work together harmoniously. This step prevents compatibility issues that could lead to system failures.

While focusing solely on performance is tempting, cost considerations should not be overlooked. Selecting connectors involves balancing performance and budget constraints carefully. This aspect is delicate but crucial. It's important to explore cost-effective options without compromising on quality or reliability. Additionally, considering long-term costs, including maintenance and potential replacements, is essential for making an informed decision.

Choosing reputable connector manufacturers is a key factor in ensuring the quality and reliability of the connectors. Established manufacturers often have a track record of producing high-quality components. Additionally, reliable manufacturers provide excellent customer support, including warranties and technical assistance. Researching and selecting a reputable manufacturer can instill confidence in the chosen connectors.

Choosing PCB connectors may seem like a small detail in the grand scheme of electronic design. Still, it's a detail that can greatly impact a system's overall performance and reliability. Understand your application needs. Both electrical and mechanical aspects matter. Take into account environmental conditions; also, balance cost considerations wisely. This approach helps you confidently choose the ideal PCB connectors. Remember, a well-chosen connector ensures that your electronic device operates seamlessly and reliably.